How To Choose a Surface Resistance Meters

How to Choose a Surface Resistance Meter?

A Surface Resistance Meter is an instrument that measures electrical resistance of an object. Surface resistance meters are commonly used to test the effectiveness of ESD control products such as auditing an ESD worksurface.

It is an important tool in manufacturing, as well as static control and ESD prevention programs because it can be used to evaluate materials and classify them as conductive, dissipative and insulative.

A quick internet search reveals many types with a wide range of capabilities and accessories. It can be difficult to choose which meter is right for your application.

Use our guide below to help with your decision. The following are topics we will cover in this article:

-

Accuracy

-

Results Display

-

Test Range

-

Voltage

-

Temperature and Humidity

-

Electrodes

-

Memory

-

Summary

1 . Accuracy: Verification vs Qualification

Not all resistance meters are created equal. Meters may be designed for quick measurements to confirm specifications (verification) while some meters are designed for more rigorous testing that requires more accurate measurements (qualification). How accurate your meter needs to be will depend on the type of testing you will be doing. Choosing a meter with higher accuracy will be a more expensive investment, it will ensure quality measurements no matter what testing required.

Below is a table that show a variety of meters with a range of functions. “Travel” meters are excellent for quick measurements and are very portable and are commonly used in verification measurements. Lab Grade meters are more accurate, include more accessories and are feature rich. Lap Grade Meters are used for qualification measurments.

|

|

|

|

SRM110Entry Level “Travel” Meter |

SRM200Mid Level |

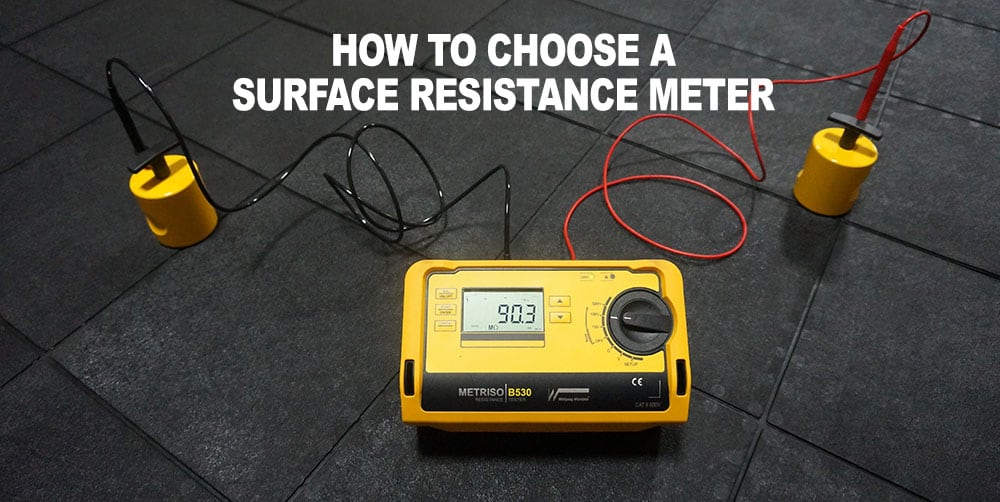

Metriso B530Entry Level |

Metriso 3000High Level |

2. Result Display: How will your meter display the measurement?

Results are measured in Ohms and are sometimes displayed in powers of 10 (also known as the decade scale). The simplest readouts show values with LED lights coded with the decade scale with colors to signify conductive, dissipative, and insulative. This readout is less accurate because the actual measurements may fall in between a decade and is rounded to the closest number. More accurate meters will display the values digitally, either in the decade scale or in Ohms.

3. Test Range

The minimum test range required for ESD purposes is 10^3 ~ 10^12 which covers conductive, dissipative and insulative items. Entry level meters will only have this range and may not display measurements in detail. For example, “Less Than 10^3” for low resistance and” Greater Than 10^12” for high resistance items. More accurate resistance meters will have a larger test range. The Metriso 3000 surface resistance meter has the largest test range we offer, from 1 Ohm ~ 1.2Tera Ohm (1.2 x 1012 ohm). The larger test range is important depending the material being tested.

4. Voltage: Choose The Right Voltage for Your Application

Surface resistance meters use voltage to test the resistance of a material. The voltage required depends on the material you are testing and the test method. Generally for ESD testing, conductive materials (1.0 x 104 ohms to <1.0 x 106 ohm) are tested at 10v and materials in the  dissipative range (≥1.0 x 106 ohm to <1.0 x 109 ohms or < 1 x 1011 ohms for packaging materials) are tested at 100v. (Learn when to use 10v and 100v). Most meters will be able to test at both 10v and 100v. They may switch between the two automatically based on the material or you may have to select the voltage manually. The verification of insulative materials may call for a higher voltage, such as 500v. There are specially designed meters for that voltage such as the Metriso 3000.

dissipative range (≥1.0 x 106 ohm to <1.0 x 109 ohms or < 1 x 1011 ohms for packaging materials) are tested at 100v. (Learn when to use 10v and 100v). Most meters will be able to test at both 10v and 100v. They may switch between the two automatically based on the material or you may have to select the voltage manually. The verification of insulative materials may call for a higher voltage, such as 500v. There are specially designed meters for that voltage such as the Metriso 3000.

Another concept to understand with resistance meter voltage is “constant voltage”. A meter that has constant voltage does not drop significantly from the selected voltage during testing. For example, when 100 volts is selected, the meter will deliver 96 and 100 volts at the probes (standard requires ±5%). Some meters, referred to as “Open Circuit”, will drop the voltage to a much lower level when the resistance of the material measured is less to protect the meter from the returning current. A meter with constant voltage is a much more accurate tool. The SRM200 surface resistance meter is a constant voltage meter and the output voltage at the probes is displayed during testing.

5. Temperature and Humidity

The humidity and temperature affect the electrical properties of the material being tested. It is possible for a material to meet the requirements at high humidity, but fail at a lower humidity. Because of this, both the ESD Association and the European CECC recognize the environmental effects on test measurements and require them to be recorded.

Some resistance meters may have the capability to test temperature and humidity built in while some do not, and external devices may be required. When in doubt, it is best to get a meter that measures temp & humidity. If your meter does not have that capability, we supply a tool that precisely measures temperature and humidity.

6. Measuring Electrodes

All surface resistance meters contact the material to be tested with components called electrodes. Electrodes can be built into a meter (called parallel electrodes) or can be external components. The electrodes you require with your meter depends on the tests you will perform.

Parallel Electrodes: Two conductive rails are built into the back of the meter and are used to give fast electrical resistance measurements. Not all meters have parallel electrodes.

External Electrodes: A variety of external electrodes can be connected to a surface resistance meter depending on the type of test. Here is a list of some external probes:

- 5lb disk probes – Most common probe (work surfaces, floors, shelves, carts, chairs, garments)

- Two point probe – for testing small areas (component trays, component tapes, non-planar surfaces)

- Hand held probe – testing resistance through a person

- Concentric ring probe – testing volume resistance. (Packaging materials)

- Glove Probe – Testing ESD Gloves (CAFÉ probe – Constant Area Force Electrode)

- Back Rest Probe – Testing ESD Chairs

- Clamp Probe – Testing ESD Fabrics/Jackets

7. Memory

Some meters record measurements in internal memory, making reporting very convenient. Recording measurements is a nice feature, but may not be necessary for everyone. Our Metriso 3000 can store 50,000 data points and includes software to create reports. Some mid- level resistance meters can also store data, such as the Metriso SRM200. The amount of data points required during your testing sessions will help you determine if you need internal memory.

8. Summary

The surface resistance meter you should choose will primarily depend on the type of test required. Do you require very accurate measurements to qualification testing or just simple measurements for verification? Will you taking large amounts of tests regularly? Or just periodically? For simple testing needs, a entry level “travel” meter such as the SRM110 will be all that is required. For higher level testing, a mid-level Travel Meter such as the SRM200 with probe accessories or a Lab Grade Testing Kit like the Metriso B530 or 3000 should be considered.