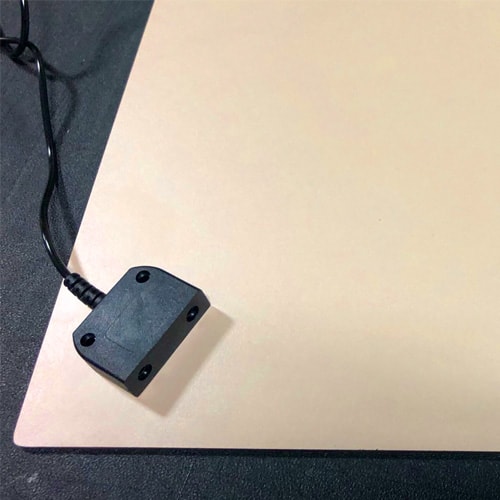

ESD Laminate Worksurface Protects your static sensitive items from ESD that could cause damage during manufacturing and assembly with a tough, but stylish Anti-static Worksurface.

Transforming Technologies’ ESD Laminate is designed for work stations where static-sensitive electronic components are manufactured and assembled. Our high pressure ESD laminate tops are the perfect answer for electronic assembly, dust-free environments for manufacturing of circuit boards and other sensitive work areas like hospitals, medical facilities, cleanrooms and laboratories. The ESD Laminate is available in beige with a radiused edge that is smooth, rounded, and free of irregularities and loose particles.

ESD Protection

Our ESD Laminate has a surface resistance (<1 x 10^9 ohms Rtg) which meets ANSI/ESD S20.20 worksurface required limit for contact with ESD susceptible items. The laminate is impregnated with a conductive layer which creates a consistent path-to-ground for static charges. In addition, the laminate resists hot solder, most solvents and fluxes.

Applications:

Creates an ESD safe work area by a providing a path-to-ground for electrical charges as well as protecting the work surface from dust and damage.