Converting

The converting industry, which involves transforming raw materials (like paper, plastic, metal, or textiles) into finished products through processes like cutting, slitting, printing, and laminating, requires anti-static products for several important reasons. Static electricity can cause dust, dirt, and debris to adhere to materials, which can damage the surface quality of finished products or contaminate them, leading to defects. Static charges can interfere with the smooth movement of materials through machinery, causing jamming or misalignment of rollers, or even damaging sensitive equipment. Anti-static products help to neutralize static charges, ensuring smooth and efficient operation. In some converting processes, especially those involving flammable materials or chemicals (e.g., printing with solvent-based inks), static discharge can pose a fire or explosion hazard. Anti-static products help to reduce the risk of sparks that could ignite volatile substances. Static electricity can cause uneven application of coatings, adhesives, or inks, leading to poor product quality or defects. By using anti-static measures, converters can ensure more uniform coatings and finishes. In processes where electronics or electronic components are involved, such as printing circuits or assembling devices, static electricity can damage delicate components. Anti-static products safeguard these components from electrostatic discharge (ESD), ensuring they function properly.

In short, anti-static products are crucial to maintaining high production standards, preventing hazards, and ensuring that the converting process runs smoothly without compromising the quality or safety of materials and products.

The converting industry uses a range of anti-static products to manage and control static electricity. Some of the most common anti-static products include:

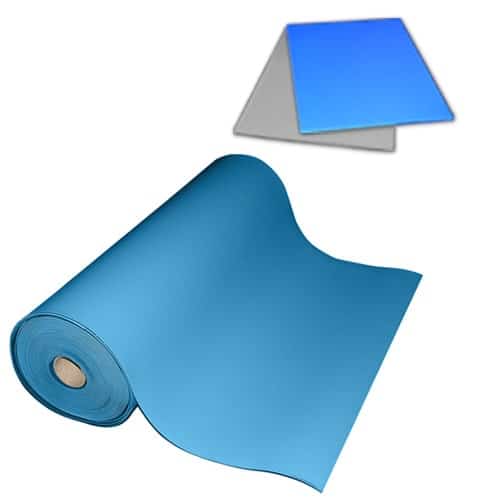

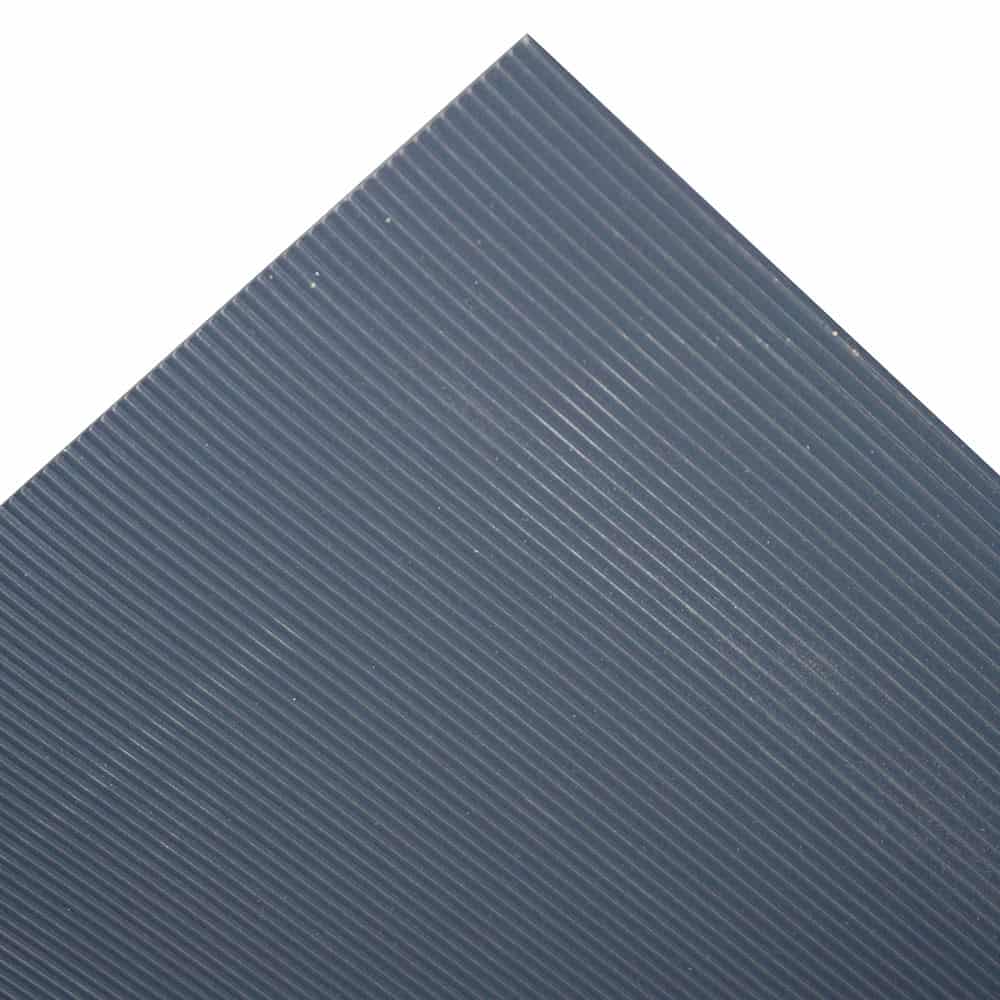

Anti-Static Mats

These are placed on floors, work surfaces, or around machinery to absorb or dissipate static charges. They help protect both workers and sensitive materials or equipment from electrostatic discharge (ESD).

Anti-Static Brushes

These brushes are designed to neutralize static electricity on surfaces by gently brushing away static charges without damaging the material. They are often used to clean films, papers, or other materials that are sensitive to static buildup.

Ionizing Air Blowers or Guns

These devices emit a stream of ionized air that neutralizes static charges on materials, making them ideal for use in high-speed production environments. Often used in printing, packaging, or coating processes where static buildup could affect material handling.

Static Dissipative Gloves

These gloves are made from materials that help dissipate static electricity, allowing workers to handle sensitive materials without introducing additional charges. Common in operations that involve sensitive electronics or materials that are prone to static charge accumulation.

Static Control Cords and Wrist Straps

Have more questions? Reach out to us and we will be happy to assist!