Critical Environments

The critical environments industry refers to sectors where precise control of environmental factors—such as temperature, humidity, particle contamination, and static electricity—is essential to ensure the proper functioning of systems, processes, or products. These environments are critical for the manufacturing or handling of sensitive materials, products, or systems. Industries that fall under the "critical environments" umbrella include pharmaceuticals, biotechnology, semiconductors, aerospace, medical device manufacturing, and cleanrooms used in various high-tech industries.

Critical environments often involve handling or manufacturing electronic, pharmaceutical, or medical devices that are sensitive to electrostatic discharge (ESD). Static electricity can easily damage delicate components, such as microchips, sensors, and pharmaceutical products that require precise conditions to maintain integrity. Static electricity can attract dust, particles, and other contaminants, which can be problematic in environments that require ultra-clean conditions (e.g., semiconductor manufacturing, pharmaceuticals, and biotechnology). These contaminants can interfere with processes, compromise product quality, and lead to defective outcomes. In certain critical environments—such as those handling flammable chemicals or gases—static discharge can pose significant fire or explosion risks. This is especially important in pharmaceutical manufacturing, chemical processing, and aerospace industries, where a static spark could lead to hazardous situations. In industries like pharmaceuticals or medical devices, static electricity can interfere with the precision needed in manufacturing processes. For instance, when handling fine powders, liquids, or medical implants, static charges can cause the material to adhere to surfaces, impacting measurements, functionality, or sterility.

The critical environments industry uses a range of anti-static products to manage and control static electricity. Some of the most common anti-static products include:

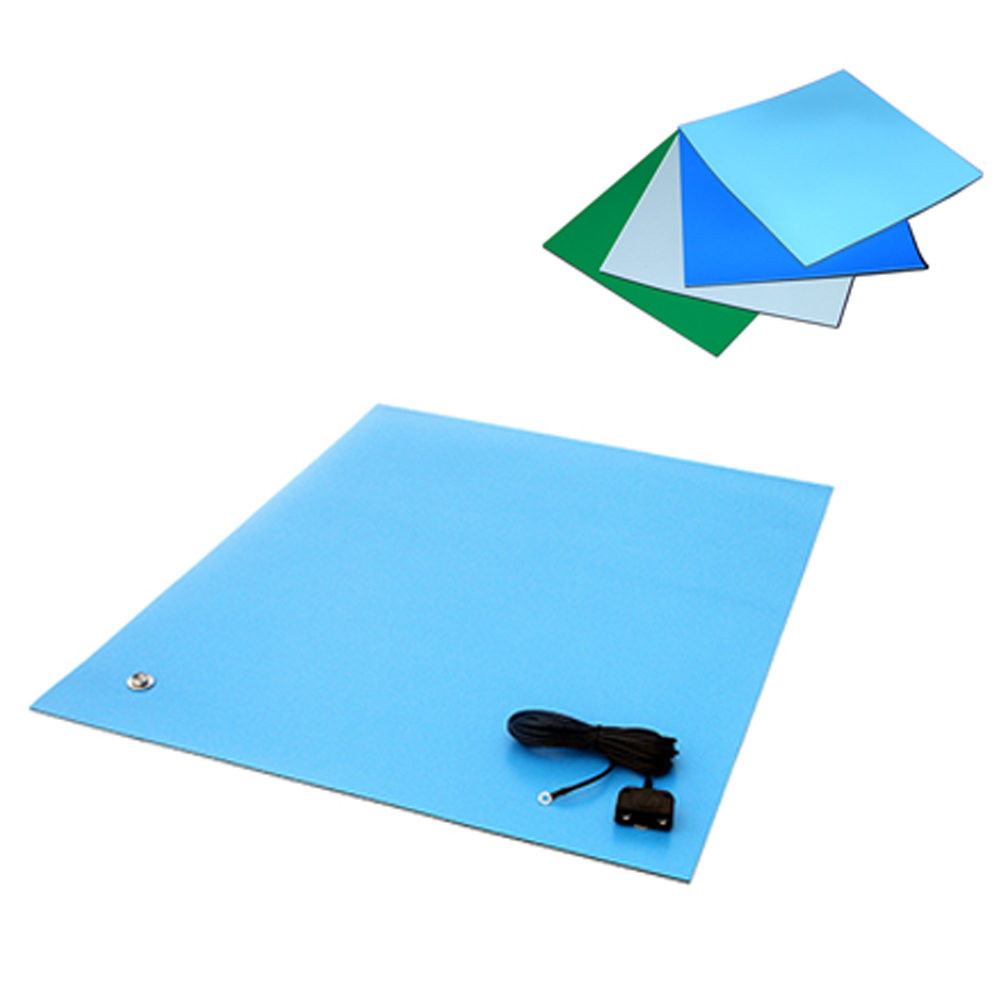

Anti-Static Mats

Anti-static mats are placed on workbenches, assembly lines, and other surfaces to prevent static buildup during product handling or assembly. These mats are designed to safely dissipate static electricity and prevent ESD damage to sensitive components, such as semiconductors, medical devices, or pharmaceutical products. Some mats are conductive, while others are dissipative, depending on the level of static control needed.

Anti-Static Brushes and Bottles

These brushes are used in critical environments to clean sensitive components without generating static electricity. The bristles of anti-static brushes are made from conductive materials that help neutralize any charge during cleaning, preventing potential ESD damage to delicate parts, such as microchips, medical devices, or semiconductor wafers.

Ionizing Air Blowers or Guns

Ionizers are commonly used in critical environments to neutralize static electricity in the air or on surfaces. These devices generate both positive and negative ions, which attach to static charges and neutralize them. Ionizers are particularly useful in large or complex environments, such as cleanrooms, where traditional static control methods like grounding are not sufficient.

ESD Gloves

For tasks that require handling very sensitive equipment or materials, workers may use ESD gloves to avoid transferring static charges. These gloves are made from materials that either conduct or dissipate static electricity, ensuring that static charges are not passed onto sensitive components or products.

Static Control Cords and Wrist Straps

Personnel in critical environments wear anti-static wrist straps to ensure that any static charge on their body is safely discharged before handling sensitive equipment or materials. These wrist straps are connected to a grounded system to allow the continuous dissipation of static electricity from the wearer.

ESD Apparel

Personnel working in critical environments wear anti-static garments, such as smocks, lab coats, gloves, shoe covers, and head coverings. These clothes are made from materials that help dissipate static charges and prevent the buildup of static electricity on workers' bodies. In cleanrooms or pharmaceutical facilities, these garments help protect both personnel and sensitive products.

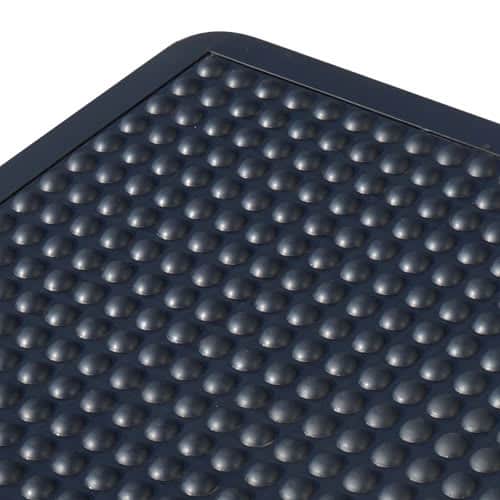

ESD Flooring

In critical environments, especially cleanrooms or manufacturing areas, anti-static flooring is installed to prevent static buildup from foot traffic. This flooring can be conductive or dissipative depending on the application. It helps to control the potential for static electricity in highly sensitive spaces and prevents the risk of ESD damage.

ESD Wipers

Anti-static wipes are used for cleaning surfaces in critical environments without introducing static. These wipes are designed to clean without generating static, which is crucial in settings where the presence of static charges could affect the results of an experiment or cause damage to products.

Have more questions? Reach out to us and we will be happy to assist!