Cleanrooms

The cleanroom industry refers to a specialized field involved in the design, construction, and operation of controlled environments known as cleanrooms. These are areas where the level of airborne particulate contamination (such as dust, microbes, and aerosols) is tightly controlled to meet specific cleanliness standards. Cleanrooms are essential in industries such as pharmaceuticals, biotechnology, electronics manufacturing (especially semiconductors), aerospace, and medical devices, where even minute particles can interfere with processes or product quality.

Cleanrooms are classified based on their cleanliness, with different standards set for allowable particle counts, humidity, temperature, and airflow. These environments are rigorously monitored to ensure that contamination is minimized, often requiring strict protocols and specialized equipment.

Many industries operating within cleanrooms deal with sensitive electronics and microelectronics (such as semiconductors, computer components, or pharmaceutical equipment). Electrostatic discharge (ESD) can permanently damage or disrupt the functioning of these components, making static control critical. Static electricity can attract dust, dirt, and particles from the air or surfaces. Since cleanrooms are designed to have minimal particle contamination, static buildup can undermine cleanliness by attracting and holding onto unwanted particles, which may interfere with critical manufacturing or research processes. In cleanrooms that handle flammable substances (e.g., chemicals or gases in the pharmaceutical or semiconductor industries), static electricity poses an ignition risk. A spark caused by static discharge could trigger a fire or explosion, leading to safety hazards for personnel and the environment. Many cleanroom operations involve highly detailed and precise work, such as assembling or testing devices. Static charges can interfere with measurements, cause parts to malfunction, or even result in defective products, which could impact overall product quality and performance.

The cleanroom industry uses a range of anti-static products to manage and control static electricity. Some of the most common anti-static products include:

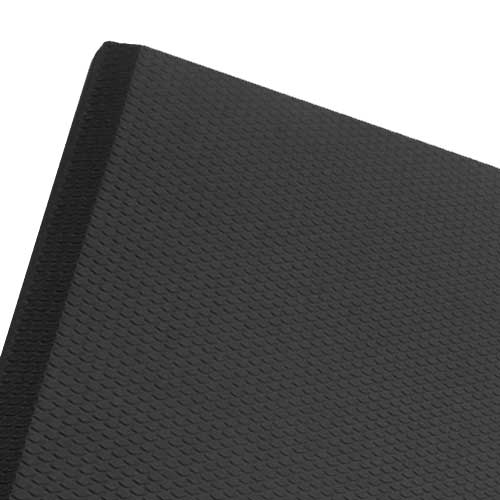

Anti-Static Mats

These are placed on floors, work surfaces, or around machinery to absorb or dissipate static charges. They help protect both workers and sensitive materials or equipment from electrostatic discharge (ESD).

ESD Apparel

Workers in cleanrooms wear special anti-static garments, such as smocks, gowns, gloves, hoods, and shoe covers. These garments are made of materials that help dissipate static electricity, preventing the buildup of static charge on the worker's body. They also help to keep contamination to a minimum by preventing particles from being shed into the cleanroom.

ESD Wrist Straps

Wrist straps are worn by personnel working in the cleanroom to ground any accumulated static charge. These straps ensure that static electricity is safely discharged before it can cause harm to electronic components or sensitive materials. They are typically connected to a grounded surface to allow for continuous dissipation of any charge.

Ionizers

Ionizers are devices used to neutralize static charges in the cleanroom environment by emitting positive and negative ions. These ions neutralize static charges on objects or the air, helping to maintain a static-free environment. Ionizers are particularly useful in areas where traditional methods of grounding (like mats or wrist straps) are not sufficient, such as large or complex equipment.

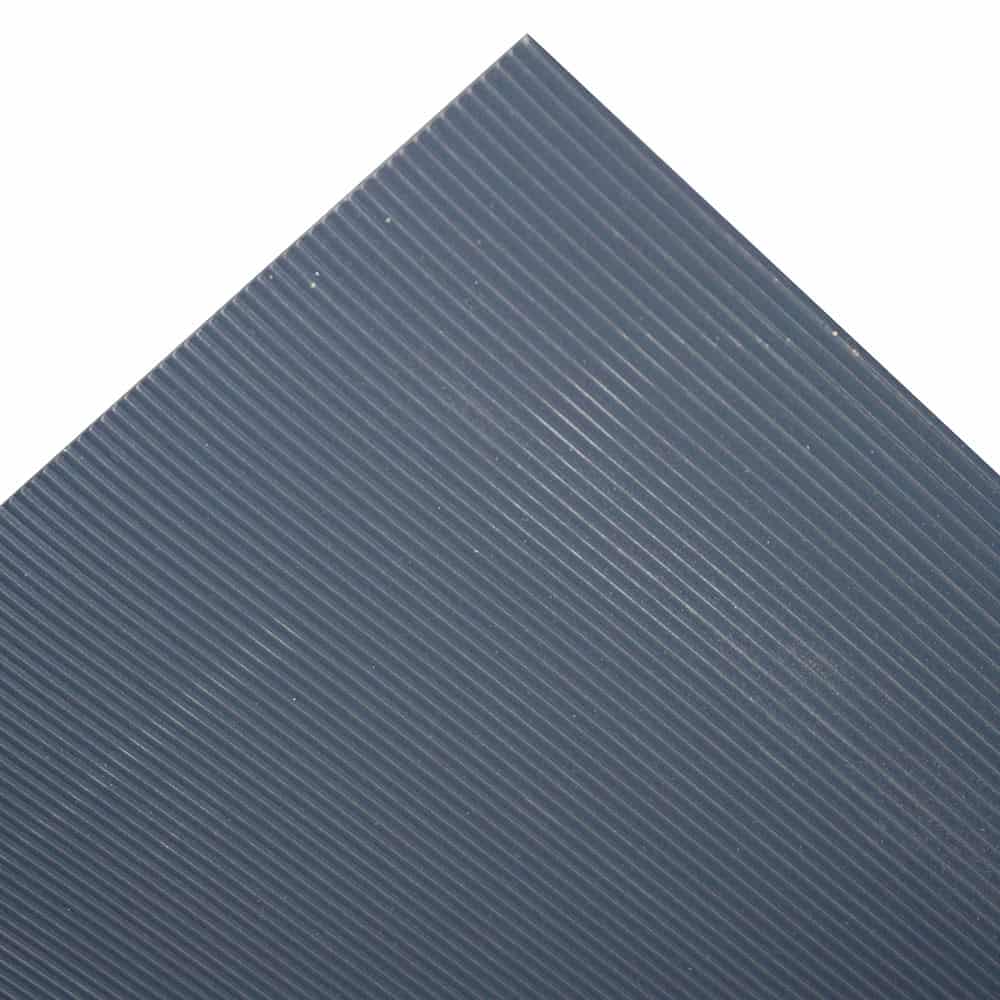

ESD Flooring

Cleanrooms often feature special anti-static or ESD-safe flooring to prevent the buildup of static charges. This type of flooring is either dissipative or conductive, ensuring that static charges are safely dissipated and not allowed to accumulate. Anti-static flooring helps reduce the risks of static discharge by preventing static buildup from foot traffic.

ESD Wipes

Wipes used in cleanrooms are designed to be low-lint and anti-static. These wipes help clean surfaces while preventing the buildup of static charges. They are particularly useful for wiping down equipment and surfaces in environments where cleanliness and static control are critical.

ESD Brushes and Bottles

Static control brushes are used to clean delicate surfaces in cleanrooms without generating static electricity. These brushes are made with conductive materials that help dissipate any charge that may accumulate during the cleaning process, ensuring that sensitive devices are not exposed to static electricity during maintenance.

Have more questions? Reach out to us and we will be happy to assist!