Automotive

The automotive industry is a broad sector focused on the design, development, manufacturing, and sale of motor vehicles, including cars, trucks, buses, and other types of transportation. It encompasses a wide range of activities, from vehicle assembly to the production of automotive parts and components, as well as the supply of related services such as maintenance, repair, and sales. The industry plays a crucial role in the global economy, providing vehicles for personal transportation, commercial use, and specialized applications.

The automotive industry uses anti-static products because static electricity can cause several issues, particularly when working with sensitive components or in environments where cleanliness and safety are critical. Modern vehicles are equipped with increasingly complex electronic systems, including sensors, chips, wiring, and control units (such as those used for infotainment systems, airbags, braking, and engine control). Electrostatic discharge (ESD) can damage these sensitive electronic components, leading to malfunction, failure, or even the destruction of the parts. In environments like automotive assembly lines, where flammable materials (such as fuels, solvents, and chemicals) are used, static electricity poses a significant safety risk. A static discharge could ignite flammable vapors or materials, potentially leading to fire or explosion hazards. Automotive parts, especially those with delicate finishes (like paintwork or precision components), can attract dust, dirt, and debris due to static electricity. This contamination can affect the quality of the final product, such as during painting, assembly, or packaging processes. Static control helps ensure smooth and efficient manufacturing operations, particularly in automated or robotic systems. Without the right anti-static products, robots and other automated equipment may face operational disruptions due to static-induced malfunctions or misalignments.

The automotive industry uses a range of anti-static products to manage and control static electricity. Some of the most common anti-static products include:

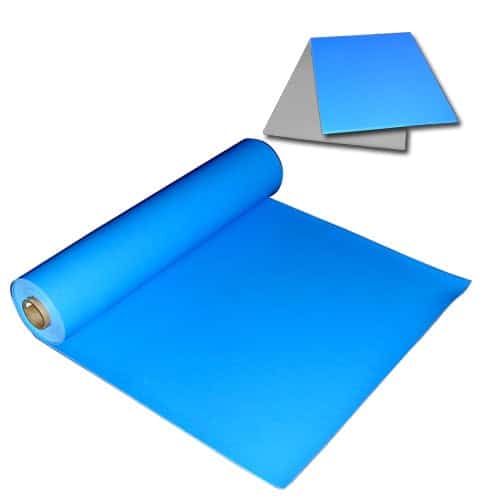

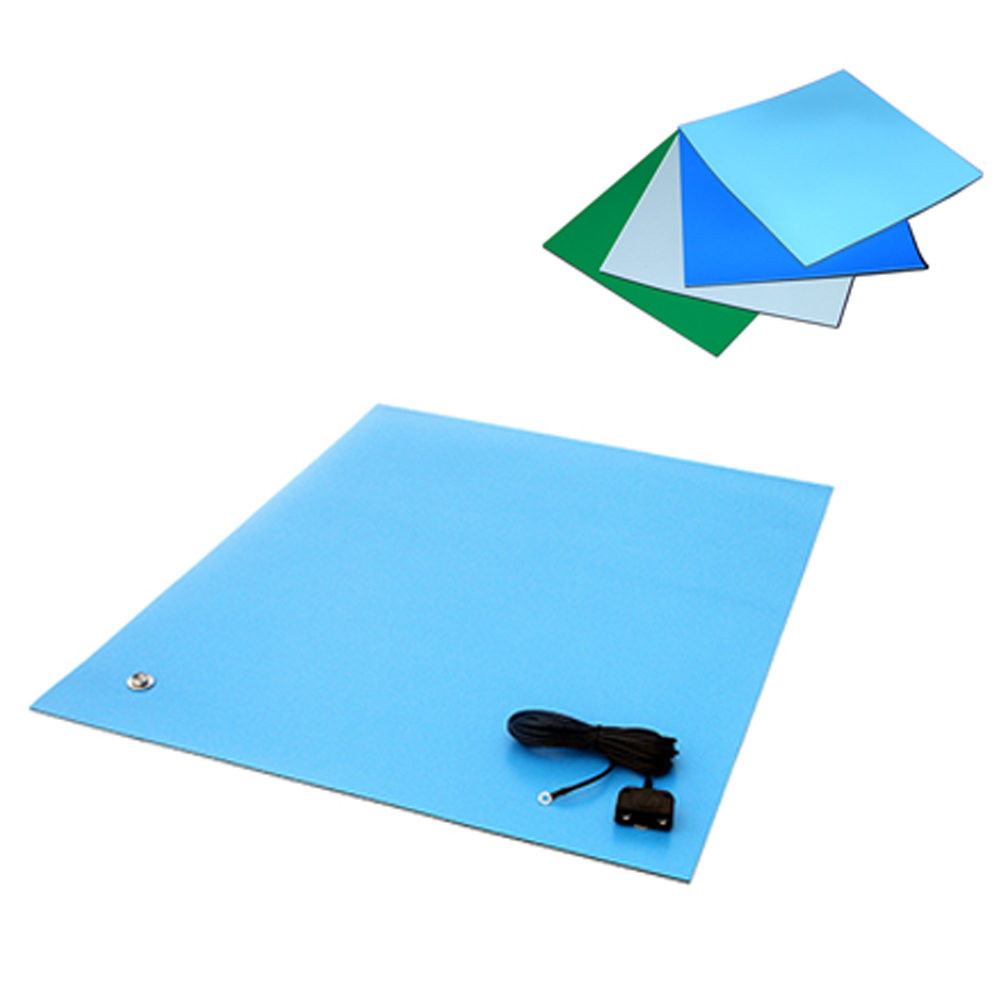

Anti-Static Mats

These are placed on floors, work surfaces, or around machinery to absorb or dissipate static charges. They help protect both workers and sensitive materials or equipment from electrostatic discharge (ESD).

Anti-static Wrist Straps

Workers in automotive manufacturing or repair environments often wear wrist straps to prevent the buildup of static electricity on their bodies. These wrist straps are grounded, ensuring any static charge on the individual is safely dissipated before they handle sensitive components, preventing damage to electronics or other parts.

Ionizing Air Blowers or Guns

Ionizers are devices used to neutralize static charges in the air, especially in assembly lines, testing areas, or storage spaces. These devices emit positive and negative ions that neutralize any static charge present in the environment, reducing the risk of electrostatic discharge. Ionizers are particularly effective in large or complex manufacturing spaces.

Anti-static Gloves and Garments

Anti-static gloves and clothing (such as smocks or lab coats) are worn by workers to prevent static from transferring onto sensitive automotive components. The clothing materials are designed to discharge static electricity safely, ensuring that no harmful charge is introduced into the production environment.

ESD Flooring

Automotive manufacturing environments often use conductive or dissipative flooring to prevent static buildup from foot traffic. This type of flooring helps maintain a controlled environment by grounding static charges safely, reducing the potential for ESD damage.

ESD Tape

Used in automotive assembly and packaging to prevent the buildup of static electricity on parts. The tape is commonly used to secure wires, components, or covers during manufacturing and to protect sensitive electronics from electrostatic discharge.

Have more questions? Reach out to us and we will be happy to assist!