TX40FR Series - ESD Cleanroom Frock

- The TX4000 Series ESD Cleanroom Frock is Designed for Controlled Environments Such as Cleanroom That Are Concerned with Static and ESD Damage

- TX4000 ESD Grid Fabric—99% Polyester / 1% Carbon

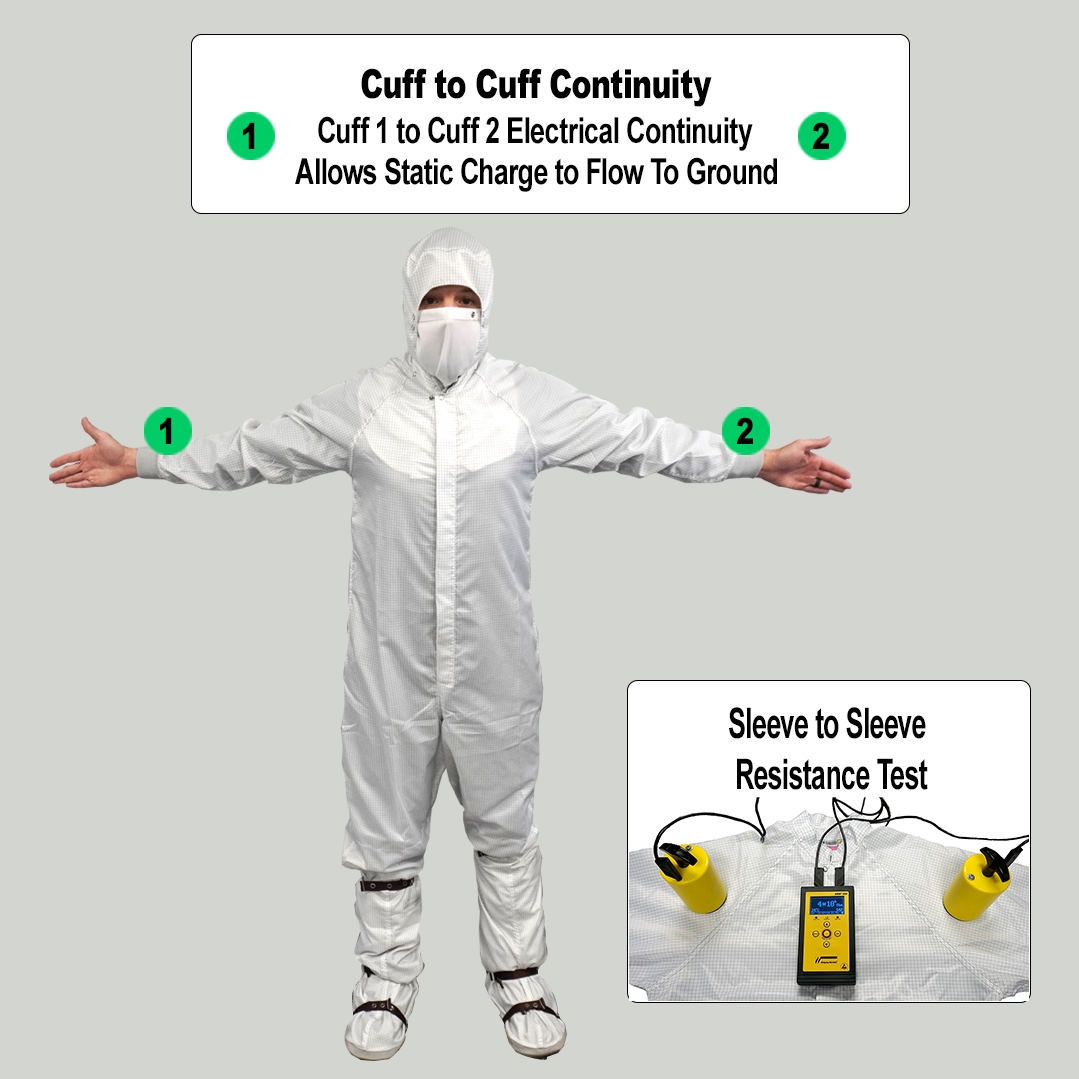

- Raglan sleeves with ESD knit cuffs for body contact

- Military collar

- Zipper closure with snaps for easy gowning

- Seams sewn with conductive threads and grounding tape for reliable panel-to-panel electrical continuity

- Sizes: XS-5XL

- Product Circularity: Reusable / Launderable

- Color: White / Navy / Light Blue*

- ISO Cleanroom: ISO 6 (Class 1000)

- Meets standards required for ANSI/ESD S20.20

The TX4000 Series ESD Cleanroom Frock is Designed for Controlled Environments Such as Cleanroom That Are Concerned with Static and ESD Damage

Transforming Technologies TX4000 Series ESD Cleanroom Frock protects the controlled environment from the number one source of contamination and static found in cleanrooms – people. Electrostatic charge is an invisible contaminant that has the potential to degrade or destroy both product and equipment, as well as attract unwanted particles. Controlling these charges on mobile operators with the TX4000 Garment System throughout the controlled environment is essential to a productive manufacturing process.

Transforming Technologies ESD Cleanroom Frock is engineered to meet up to a Class 1000 cleanroom demands for industries such as microelectronics, semi-conductors, disk drives, laser, and similar industries. The Cleanroom Frocks are made with a high-end static dissipative grid fabric for eliminating static on the wearer in cleanrooms and shielding static charges generated while moving.

The frock features a military collar, ESD knit cuffs, and YKK zipper closure with adjustment snaps at the neck.

ESD Cleanroom frocks made specifically for static control

The frocks are made with conductive nylon fibers woven throughout the material, providing continuous and consistent charge dissipation. All of the seams in the frock are designed to maintain electrical continuity from panel-to-panel and from sleeve to sleeve in accordance with the ESD Association Garment Standard, ANSI/ESD STM 2.1 If this continuity is lost, an ESD jacket can become an isolated charged conductor and a major ESD threat. Transforming Technologies eliminates this threat by sewing the seams of the frock with conductive thread.

Superior workmanship and reliable panel-to-panel continuity makes the TX4000 ESD Cleanroom Frock an excellent product to control contamination and static. The 6200 Series Garment maintains consistent continuity readings for up to 100 wash cycles.