Industries Concerned With Static & ESD

Static Electricity can be a problem in many industries. It can slow production, reduces product quality, increases warranty claims, attract contaminants and can pose a safety threat from shocks to operators or even explosion. Static issues in industry is commonly referred to as ESD or Electrostatic Discharge, and is the result of a sudden transfer of an electric charge from one conductive surface to another.

It may not be a commonly thought of problem, but it is a well-known phenomenon throughout the electronics, plastics, packaging, printing, paper, medical, pharmaceutical and textile industries.

Electronics Manufacturing

Electronic devices such as computers and cell phones are becoming smaller and faster every year and more at risk to ESD. Static can burn tiny holes into sensitive electronic components like circuit boards which can cause a catastrophic failure or worse a latent failure – a failure that happens after the device is in the consumers hands – which causes increased warranty claims and a lack of confidence in a brand. Companies manufacturing electronics require ESD protection in their quality programs.

Medical Device Manufacturing

Uncontrolled static attraction is a particular problem for plastics industries, and consequently, for medical device manufacturers. Even in the most stringent cleanrooms, static charge attracts particulates from people, processes and equipment, so it is important to take appropriate measures to ensure static is kept to a mini-mum, if not completely eliminated. Medical device manufactures are committed to quality and static can ruin their products.

Automotive & Aviation

Transportation vehicle manufacturing such as automotive and aviation is affected by static at every stage of production. Static can cause contamination of components such as dash boards, windshields and headlights, ruin paint jobs and cause process errors in high speed assembly. And we have not even mentioned the electronics. Today, auto electronic systems and engine computers do everything from regulating fuel to diagnosing problems. And they can all be damaged by static electricity.

Cleanroom & Critical Environments

Critical environments range from laboratories and clean rooms to hazardous areas with explosive chemicals or gun powder. Neutralizing static in these areas is crucial. One spark from a static charge could in many cases result in fire or explosion and serious injury or death. Dust and contamination are two of the biggest nightmares for anyone working in a cleanroom environment. Unfortunately static electricity is one of the largest contributors in attracting airborne contaminants, therefore a static build up in a clean room production environment can be a disaster.

Printing and Painting

Static electricity can cause a wide range of issues in printing and painting applications. From statically charged substrates, to dust attracted to the static charge. Ink fly, hidden voltage and a number of other static problems across all types of print. Static is the invisible enemy of the perfect paint finish! Static charge is a major cause of paint film contamination, however all these other problems can also be caused by static: Non-consistent lay down of metallic, blending/color matching problems, un-even application of material, dark edges, patchiness.

Plastics

Static electricity and plastic are intrinsically linked and there are few (if any) plastic manufacturing processes that do not suffer adverse effects from the build up of a static charge. Plastic is the best example of insulative materials, which are the largest contributor to ESD. Static effects Injection molding, blow molding, thermoforming, rotational molding, parts conveying and collection and assembly processes and many more. On top of that, static may cause dust attraction and contamination, product rejection, process errors and operator safety concerns.

Packaging & Fulfillment

Static issues in packaging can be costly and time consuming in an industry where speed is paramount. Static can prevent packages from filling correctly, or cause product to veer off the intended course. Static can also cause sealing issues and can create numerous problems with label printers, shrink wrappers, containers and webs. Static can also develop on conveyors and transport devices, cause items to stick or even shock operators in the area.

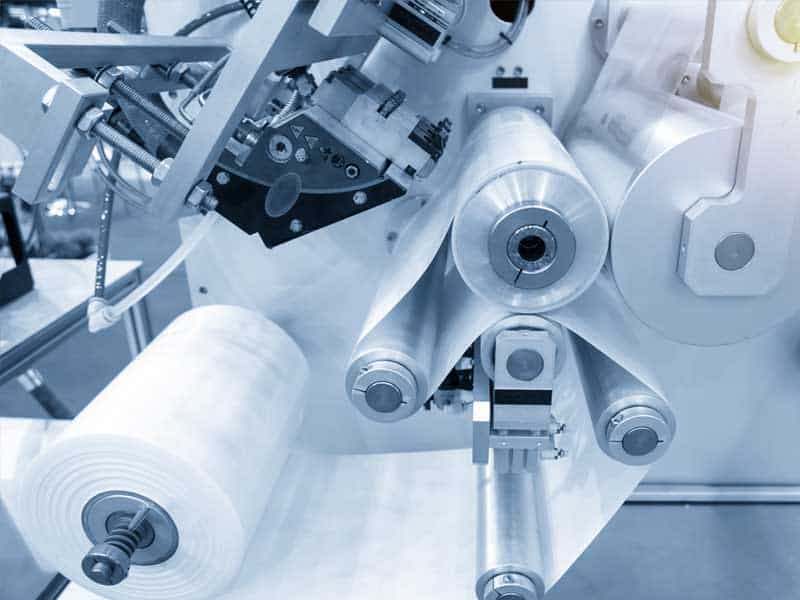

Converting

Eliminating static in a converting process is essential. Due to the nature of converting, high levels of static electricity are often generated by the fast moving web passing over rollers and through slitters. The challenge facing converters often involves finding the balance between the process speed and capability of the static control equipment.